Dunham Lab Chemostat Manual

Maitreya Dunham and Emily

Mitchell

Last revised December 2010

This comprehensive manual covers the entire process of

running a chemostat, including media recipes, chemostat setup, inoculation,

data acquisition and storage, daily monitoring, harvests for DNA and RNA, and

data analysis. Although it was written with our blown-glass chemostats in mind,

many of the procedures are general, and the principles could be applied to

other systems. If you have edits,

additions, or suggestions for the manual, please email me at maitreya@uw.edu

Please feel free to point other people to these

instructions. Also, I would

appreciate the citation if you use any of this information in a publication or

talk.

Visit http://dunham.gs.washington.edu

for the most recent updates to the manual and for my other protocols on

microarrays and yeast genetics.

Also available is the old version of the chemostat manual, which covers

use of ATR Sixfors Fermenters.

That portion of the manual has forked and is now maintained by the

Botstein lab.

Thanks to Matt Brauer, my long-time companion in the

chemostat lab, for help developing these protocols. Also thanks to Frank Rosenzweig who taught me how to run my

first glass-blown chemostats. Many

of the protocols were influenced by his chemostat aesthetic. Finally, many members of the Botstein

and Dunham labs contributed improvements.

Edits since last version: My new set up at the University of

Washington employs blown glass chemostats, and so this manual has been updated

to focus on their use and care.

copyright

Maitreya Dunham 2010

Planning the experiment...................................................................... 5

Signup................................................................................................... 5

Strains.................................................................................................. 6

Table 1.

Yeast strains for the chemostat............................................................... 6

Limitations............................................................................................. 7

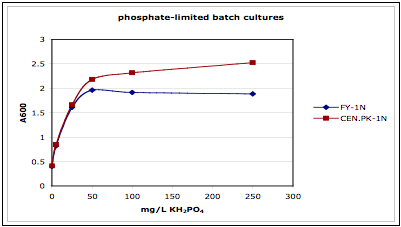

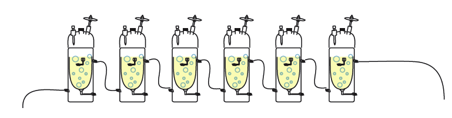

Figure 1.

Testing the limitation in batch................................................................. 8

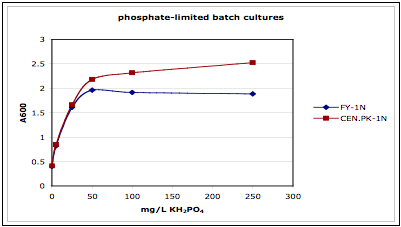

Figure 2.

Testing the limitation in the chemostat.................................................. 9

Dilution Rate.......................................................................................... 9

Chemostat

media................................................................................. 11

Salts................................................................................................... 12

10X salts for phosphate limitation (1 L)............................................... 13

10X salts for sulfur limitation (1 L)...................................................... 13

10X salts for nitrogen limitation (1 L).................................................. 13

Additives.............................................................................................. 14

Metals............................................................................................. 15

Vitamins.......................................................................................... 16

Setting up a run.................................................................................. 17

Mixing and

Filtering the media.................................................................... 17

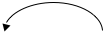

Prepping a new Carboy...................................................................... 18

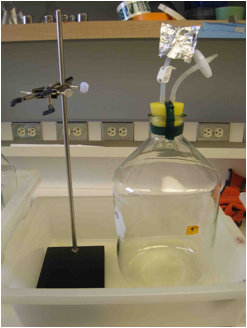

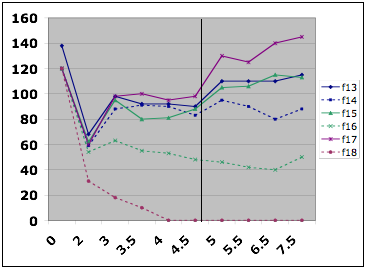

Figure 3.

Setting up the carboy............................................................................. 18

Foil Origami..................................................................................... 19

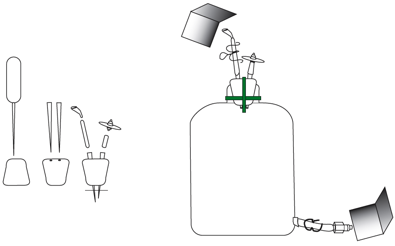

Figure 4.

Foil Origami............................................................................................ 19

Preparing a Carboy for Media............................................................. 20

Fetching Water................................................................................. 20

Mixing the Media.............................................................................. 21

Filtering the Media............................................................................ 21

Ready, set,

filter:........................................................................................................ 22

Figure 5.

Getting ready to filter, The Carboy........................................................ 22

Figure 6.

Setting up the filter................................................................................. 23

Figure 7.

Final assembly of filter set up................................................................ 24

Figure 8.

Turn Vacuum on LOW............................................................................ 25

Figure 9.

During filtration....................................................................................... 26

About the Chemostats......................................................................... 27

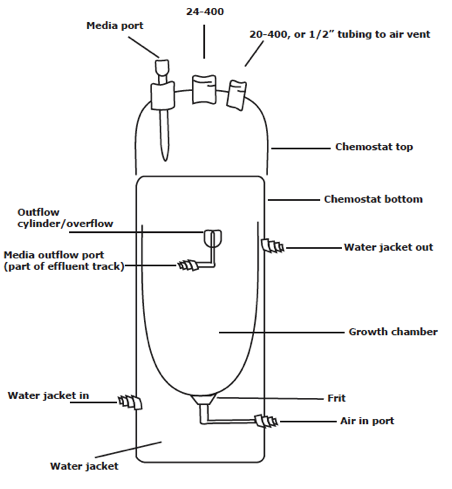

Figure 10.

The three systems of a chemostat..................................................... 27

Figure 11.

Anatomy of a Chemostat..................................................................... 28

Setting up

the Chemostats.................................................................. 28

Prepping a

new chemostat.......................................................................... 29

Table 2.

Working volumes of Unaltered Chemostats........................................... 30

Figure 12.

Downward angle of effluent track......................................................... 31

Clearing the

way for aeration.................................................................... 31

Cleaning the Bubblers....................................................................... 32

Baking the frit.................................................................................. 32

Setting up a

Chemostat for a Run................................................................ 33

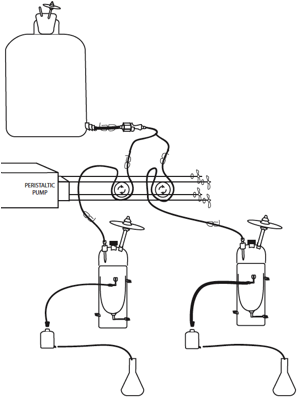

Figure 13.

Set up new pump tubing....................................................................... 34

Figure 14.

Two chemostats running off of one carboy......................................... 35

Filling the chemostats........................................................................ 36

Inoculation....................................................................................... 37

Starting the pumps........................................................................... 37

Setting the

Pump Rate............................................................................................... 37

Table 3.

Example Pump rates for Chemostats..................................................... 38

Loading the

Pump Heads........................................................................................... 38

Starting the

Pump...................................................................................................... 39

Figure

15. Dummy lines........................................................................................ 40

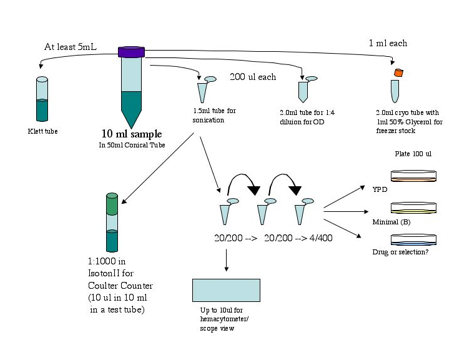

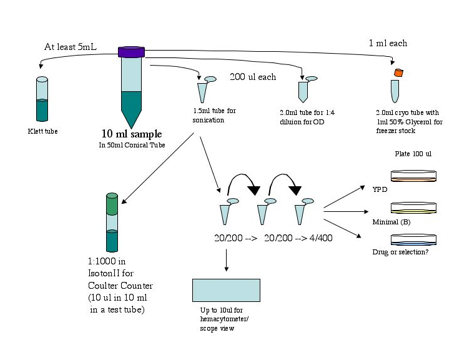

Sampling the Chemostats.................................................................... 41

Figure 16.

Taking a sample during a run.............................................................. 41

Preparing to sample................................................................................. 42

Figure

17. Example of Minimal sampling......................................................... 43

Figure 18.

Experiment Layout Sheet.................................................................... 43

Figure 19.

Header index card................................................................................ 44

Figure 20.

Sampling index card............................................................................. 44

Sample tracking................................................................................ 45

Contamination issues........................................................................ 45

Figure 21.

Checking for media line occupancy.................................................... 46

Klett................................................................................................ 46

Glycerol stock................................................................................... 47

Spectrophotometer............................................................................ 47

Sonicator......................................................................................... 47

Coulter Counter................................................................................ 48

Plating for viable counts..................................................................... 48

Plating for drug resistance.................................................................. 49

Sampling for DNA.............................................................................. 49

Sorbitol

Solution......................................................................................................... 49

Sampling for RNA.............................................................................. 49

Figure 22.

Small filtering apparatus...................................................................... 50

Cleanup after sampling..................................................................... 51

Counting colonies............................................................................. 51

Example of daily sampling................................................................. 51

Sample

Analysis During a Run..................................................................... 52

D = effluent

volume/(time * chemostat volume)...................................................... 52

Media

Replacement.................................................................................. 53

Harvest............................................................................................... 54

What is 'Steady

State'.............................................................................. 54

How long

should Evolutions go?................................................................. 55

Setup for harvesting............................................................................... 55

Figure 23.

Large Vac kit........................................................................................ 56

Harvesting............................................................................................ 56

Figure 24. 'Harvest

Cart' complete with the large filter apparatus..................... 57

Cleanup............................................................................................... 58

Taking down chemostats:.................................................................. 59

Taking down

all the chemostats:.............................................................................. 61

Sample

Processing.................................................................................. 61

Chemostat Troubleshooting.............................................................. 63

Appendix

A: Sample processing........................................................ 65

Culture revival...................................................................................... 65

Coulter

Counter Instructions................................................................... 66

Troubleshooting the Coulter Counter................................................... 68

Testing Filtrates.................................................................................... 69

DNA prep.............................................................................................. 70

Lysis buffer for DNA........................................................................... 71

RNA prep.............................................................................................. 72

Lysis buffer for RNA........................................................................... 72

RNA prep for 5 ml daily samples............................................................................... 73

RNA prep for 50 ml harvest....................................................................................... 74

Appendix

B: If we had it to do over again...................................... 75

The Disaster

Index-Where you don't want to be............................................... 75

Cork Sucking.................................................................................... 75

Figure 25.

Hacking at the Cork............................................................................. 75

Pump problems................................................................................ 75

Media line contamination................................................................... 76

Figure 26.

Major media line occupation................................................................ 76

Breakage......................................................................................... 76

Changes to

the chemostat design................................................................. 77

Consistent chemostat volumes........................................................... 77

Table 4. Distances between frit and overflow...................................................... 77

Media line dropper............................................................................ 77

Appendix C:

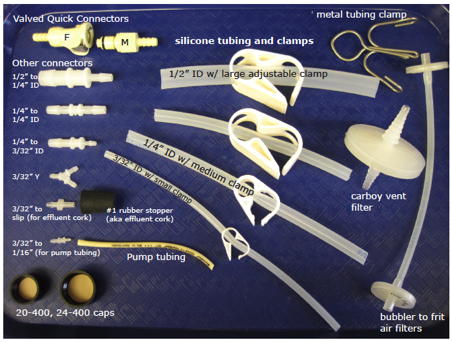

Parts and Suppliers....................................................... 78

Tubing and

Fittings................................................................................. 78

Figure 27.

Tubing and fittings............................................................................... 78

Supplies and

Suppliers.............................................................................. 79

Chemostat References........................................................................ 85

The first thing to do is design your experiment. You need to choose a strain, a

limitation, a limiting nutrient concentration, and a dilution rate. Figure out how much media you'll need,

and arrange to use the chemostats.

Don't try to sign up now, and figure it out later, because you'll end up

regretting it. Take the time to

read through the manual, and understand the full experiment before you sign up.

When you've read through the manual, arrange to speak with

someone in the lab who is practiced with the chemostats, so they can help

you. For your first chemostat

experiment, plan to run no more than 4 chemostats, and coordinate with someone

for setting up, starting the run, and sampling. Then you'll be pretty much on your own until the end of the

experiment, when you'll want someone to go over the clean up/ recovery stage.

Once you've got an experiment planned, sign up on the Chemostat

sign-up calendar. That way, other

people can plan their own chemostat use.

List your name, which chemostats you'll want to use, and for how

long. Include time for preparation

and clean up in your timeline.

The strains commonly used in the lab are FY, which is an

S288C derivative that's been made GAL2+, and CEN.PK, a favorite of the European

chemostat community. Using a

prototroph is vastly preferred to using an auxotroph. With auxotrophs, you can never really be sure what the cells

are using as a source of limiting nutrient. It just complicates matters and makes you less sure of any

results. We have prototrophs of FY

and CEN.PK, as diploids and as haploids of both mating types, in the strain

collection:

|

Background

|

Mating type

|

AKA

|

DBY number

|

|

FY

|

a/alpha

|

FY4xFY5

|

YMD 132

|

|

FY

|

a

|

FY4

|

DBY 11069

|

|

FY

|

alpha

|

FY5

|

DBY 11070

|

|

CEN.PK

|

a/alpha

|

|

DBY 9500

|

|

CEN.PK

|

a

|

|

DBY 11092

|

|

CEN.PK

|

alpha

|

|

DBY 11093

|

Table

1. Yeast strains for the

chemostat.

The FY haploid strains are from Fred Winston. The CEN.PK diploid, DBY9500, is direct

from Peter Kotter. The FY diploid

and the CEN.PK haploids were derived in my lab by mating and dissection, respectively.

Both strain backgrounds grow well in glucose, phosphate, and

sulfur limitation. Oddly, CEN.PK seems to behave better than FY in nitrogen

limitation. All S288C derivatives

have a Ty element in HAP1 that

decreases its activity. We now

also have a HAP1+ derivative of FY

from Fred Winston's lab. CEN.PK

strains have a mutation in CYR1. Also, LEU2 may not be in the usual location.

You can, of course, use other strains, and we have. The biggest unknown danger of a new

strain is its flocculation capacity.

Because they can stick to the vessel and sink to the bottom to avoid

being diluted out, clumpers are selected for in the chemostat. In addition to complicating cell count

data, they also make it very difficult to understand what's going on in terms

of selection pressure, clonal selection, etc., so the chemostat run is

effectively over once they appear.

For CEN.PK and FY, I've gotten clumpers occasionally ~400 generations

into the evolutions. Many lab

strains carry knock outs of several FLO genes, making the transition to

flocculation difficult (although some of the knock out mutations, like the one

in FLO8 in S288C, are point mutations

that may revert). Other strains,

such as SK1, frequently flocculate, making them next to useless in the

chemostat. When using a new strain,

be particularly vigilant about frequently checking the culture with the

microscope before and after sonication.

If sonication effectively breaks up the clumps, it's probably not a

serious enough problem to halt the chemostat, although you should make a note

of the phenotype in your log. For

short-term cultures, this is not nearly as much of a problem, so you have a

wider variety of strains available.

If you do have to use an auxotroph, be very careful with the

supplements you add. For example,

you can't use adenine sulfate with sulfur limitations. You want to make sure the culture does

not become limited for the additive, but you don't want to add so much excess

that the culture eats the additive instead of the nominal limiting

nutrient. See the Limitations

section for how to check limiting nutrients. You can also use an auxotroph on

purpose and limit with the additive it requires. Matt Brauer and Alok Saldanha have successfully done this

with leu2 strains, and Alok and I

have also done ura3 strains. These

media formulations are included in the Media Recipes section.

Limitations

The limiting nutrient depends on what your experiment

is. Keep in mind that glucose

limited cultures seem to be most sensitive to changes in the dilution

rate. Lower dilution rates provoke

more respiration while higher dilution rates favor fermentation. Nitrogen limitation does not work well

with FY in my hands, though others have had more success.

If you are not using one of the standard recipe/strain

combinations listed in the Chemostat Media section, you should do a preliminary

batch culture experiment to figure out the limiting concentration to use. Inoculate an overnight culture. Spin it down and resuspend at a 100X

dilution in chemostat media without any limiting nutrient. Aliquot equal volumes into a series of

appropriate volume shake flasks that contain different quantities of the

limiting nutrient. Be careful that

the volumes of limiting nutrient solution are the same in all the flasks so you

don't get different dilution factors.

You may want to make your media 1.1X and bring them to 1X with the

limiting nutrient solution. Let

these flasks shake at 30C for a couple of days or until the density

stabilizes. You want

them

to be completely in stationary phase.

Measure the densities. If

you graph the concentration of limiting nutrient vs. the final densities of the

cultures, you should get a plot with a linear range, a nonlinear range, and a

plateau. You want to stay in the

linear range. Here's

representative data from one of the experiments for phosphate limitation:

Figure 1. Testing the limitation in batch.

Note that the Y-intercept is not zero. That's probably from nutrient the yeast

stored from the overnight culture, which was in rich media in this

experiment. Take that into account

when you decide on a chemostat media concentration that will yield your desired

density. We aim to run our evolutions starting from a population size of 3-5x107

cells/ml. To measure the final

density more exactly, once you have a good idea of what concentration is

limiting, grow the first overnight in limiting chemostat media. The cells will use up all the limiting

nutrient and the zero will really be zero.

Although the batch results generally match the chemostat

quite well, make sure to test the concentration in the chemostat to double

check that it's really limiting.

As a cautionary tale, we lost over a year of work from failing to

properly do this control: a typo in the phosphate limitation media recipe

resulted in a low potassium concentration, an error that had no effect on the batch

culture results yet profoundly affected the chemostat cultures. To convince yourself that your

chemostats are limited by what you think they are, run 2 chemostats to steady

state. Once they've hit steady

state, in one chemostat, increase the nominal limiting nutrient in the feed

media by 50% and watch for an increase in density. In the other, increase the sugar, vitamins and metals by 50%

and see if the density changes. If

you are truly limited only for the limiting nutrient, you will see ~50% increase

in density in the first one but no change in density in the second one. Density is actually not the greatest

indicator since it's really yield you're interested in, but it usually does

track pretty well. Klett seems to

work the best as a surrogate for yield.

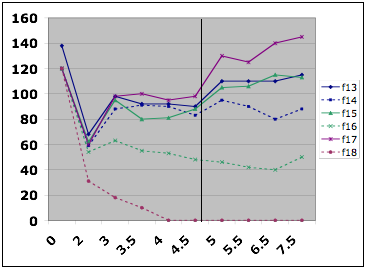

In this

example from David Hess, six cultures were grown to steady state with 20 mg/L

potassium phosphate. At the

indicated point, the feed media was switched to 30 mg/L potassium phosphate. F13, F15, and F17 are all limited by

phosphate. F14 and F16 are

not. F18 washed out.

In this

example from David Hess, six cultures were grown to steady state with 20 mg/L

potassium phosphate. At the

indicated point, the feed media was switched to 30 mg/L potassium phosphate. F13, F15, and F17 are all limited by

phosphate. F14 and F16 are

not. F18 washed out.

Figure

2. Testing the limitation in the chemostat.

Also note that not all strains behave exactly the same. In some circumstances, it may be easier

to run two separate chemostats, each with a different (supposedly limiting)

concentration of the nutrient.

Then compare the steady state densities. This experimental design is particularly useful when the

strains take a long time to hit steady state and so evolution is a concern.

We most typically use a dilution rate of 0.17 (+/-) 0.01

chemostat volumes per hour. The

Paquin and Adams experiments were all at 0.2 chemostat volumes per hour. You will know if you set the dilution

rate too high (i.e., above the maximal growth rate) because your culture will

wash out. In glucose limitation,

there is a critical dilution rate where the culture switches from

respirofermentative growth to primarily fermentative growth. Growth-rate dependent changes have been

studied in great detail by the Botstein, Oliver, and Regenberg labs.

The dilution rate is a simple relation of the effluent

volume, length of time (in hours) effluent collected, and chemostat volume:

D = effluent volume/(time * chemostat volume)

The dilution rate is in units of hr-1. It is also sometimes called omega.

Chemostat media has 4 components that need to be made

separately: salts, metals,

vitamins, and carbon/sugar.

For each batch of media, you will prepare a carboy, thaw the

1000X vitamins, make 10X salts, and make 10X carbon source. You'll combine these with the pre-made

metals and vitamins, and top off to 10L with glass distilled water. It all gets mixed together in a

non-sterile "mixing" carboy before it gets filtered into a sterile

carboy.

These media recipes come from Julian Adams via Frank

Rosenzweig with further modification by me. The glucose limitation recipe is exactly per Adams. I modified the glucose limitation

recipe for phosphate, sulfur, and nitrogen limitation. In general, I tried to keep all ions at

the same molarity where possible.

The Adams version of the phosphate limitation recipe uses the salts at

0.25X to limit the effects of phosphate contamination from the other salts, but

I always use 1X salts for everything.

You can only get away with this if you use really pure chemicals.

The Adams recipe handed down to me also had a typo in it,

which we didn't catch until 2005.

The potassium concentration was 10X lower than it should've been. If

you used my phosphate-limited media recipe prior to December 2005, that recipe

was wrong! I'm very sorry

about that.

The uracil and leucine limitation recipes use the Adams

glucose limitation base plus limiting concentrations worked out by Alok

Saldanha.

Salts can be made as 10X stocks in glass distilled water and

kept at room temperature until use.

Nonsterile salts should be used within a couple weeks to avoid

contaminant growth. You may be

tempted to make a big carboy of salts, but that experiment has been tried and

mysterious floating bits appear eventually. If you want to keep them longer, they can be autoclaved.

Make salts using the purest chemicals available. It is crucial that limiting nutrient

concentration not vary due to contamination in other salts.

10X salts for carbon,

leucine, or uracil limitation (1 L)

|

1 g

|

calcium chloride.2H2O

|

|

1 g

|

sodium chloride

|

|

5 g

|

magnesium sulfate.7H2O

|

|

10 g

|

potassium phosphate monobasic

|

|

50 g

|

ammonium sulfate

|

|

1 g

|

calcium chloride.2H2O

|

|

1 g

|

sodium chloride

|

|

5 g

|

magnesium sulfate.7H2O

|

|

50 g

|

ammonium sulfate

|

|

10 g

|

potassium chloride

|

|

100 mg

|

potassium phosphate monobasic (to 10 mg/L final)

|

|

1 g

|

calcium chloride.2H2O

|

|

1 g

|

sodium chloride

|

|

4.12 g

|

magnesium chloride.6H2O

|

|

40.5 g

|

ammonium chloride

|

|

10 g

|

potassium phosphate monobasic

|

|

30 mg

|

ammonium sulfate (to 3 mg/L final)

|

|

1 g

|

calcium chloride.2H2O

|

|

1 g

|

sodium chloride

|

|

5 g

|

magnesium sulfate.7H2O

|

|

10 g

|

potassium phosphate monobasic

|

|

400 mg

|

ammonium sulfate (to 40 mg/L final)

|

Additives include the carbon source, vitamins, and

metals. The following recipes are

the standard limitations. Additives should be COMPLETELY dissolved before

mixing and filtering.

Additives

for sulfur, phosphate, and nitrogen limitations

(for 10 L media)

|

50 g

|

glucose (to 0.5% final)

|

|

10 ml

|

1000X vitamins

|

|

10 ml

|

1000X metals

|

|

|

|

Glucose (dextrose) limitation additives

(for 10 L media)

|

8 g

|

glucose (to 0.08% final)

|

|

10 ml

|

1000X vitamins

|

|

10 ml

|

1000X metals

|

|

|

|

Leucine

limitation additives

(for 10 L media)

|

150 mg

|

leucine (to 15 mg/L final)

|

|

50 g

|

glucose (to 0.5% final)

|

|

10 ml

|

1000X vitamins

|

|

10 ml

|

1000X metals

|

Uracil

limitation additives

(for 10 L media)

|

50 mg

|

2 mg/ml uracil (to 5 mg/L final)

|

|

50 g

|

glucose (to 0.5% final)

|

|

10 ml

|

1000X vitamins

|

|

10 ml

|

1000X metals

|

Metals are made as a 1000X stock that keeps at room

temperature for at least a year.

Keep the bottle well wrapped in foil since some of the metals are light

sensitive. Make the metals in

sterile glass distilled water. Be

vigilant about shaking before using since the metals will not totally dissolve.

1000X

metals

(1 L)

Dissolve chemicals in ~1 L stirring glass distilled water in

the following order:

|

|

Metal

|

Chemical storage

|

|

500 mg

|

boric acid

|

RT shelf

|

|

40 mg

|

copper sulfate.5H2O

|

RT shelf

|

|

100 mg

|

potassium iodide

|

RT, dark, dessicator

|

|

200 mg

|

ferric chloride.6H2O

|

RT shelf

|

|

400 mg

|

manganese sulfate.H2O

|

RT shelf

|

|

200 mg

|

sodium molybdate.2H2O

|

RT shelf

|

|

400 mg

|

zinc sulfate.7H2O

|

RT shelf

|

Bring total volume to 1 L with glass distilled water, and

pour into a bottle. Cover the

bottle with foil, and store at room temperature.

Vitamins are also made as a 1000X stock. The solution is aliquoted into 50 ml

Falcon tubes and stored at -20C.

Don't fill the tubes to the top, or else the lid will split when

frozen. The "working tube"

can be stored at 4C. The vitamins

will not dissolve completely, so shake before use. Care should be taken to keep the solution well mixed while

aliquoting.

1000X

Vitamins

(1 L)

Weigh all chemicals and add to a beaker of stirring glass

distilled water to dissolve as much as possible. Top off to 1 L, then aliquot about 40 mL per 50 mL tube, and

freeze.

|

|

Vitamin

|

Chemical storage

|

|

2 mg

|

biotin

|

4C

|

|

400 mg

|

calcium pantothenate

|

4C

|

|

2 mg

|

folic acid

|

RT, dark, dessicator

|

|

2000 mg

|

inositol (aka myo-inositol)

|

RT shelf

|

|

400 mg

|

niacin (aka nicotinic acid)

|

RT shelf

|

|

200 mg

|

p-aminobenzoic acid

|

4C

|

|

400 mg

|

pyridoxine HCl

|

RT, dark, dessicator

|

|

200 mg

|

riboflavin

|

RT shelf

|

|

400 mg

|

thiamine HCl

|

RT, dark, dessicator

|

It takes 5 days to run a standard short-term chemostat from

inoculation to harvest, plus a few days of preparation. A convenient schedule might be:

|

Thursday

|

Start 10X salts dissolving ON. Thaw vitamins. Prep carboys

and chemostats.

|

|

Friday

|

Autoclave carboys and chemostats. Filter media. Set up and fill

chemostats. Start inoculum.

|

|

Saturday:

|

Inoculate.

|

|

Sunday:

|

Start pumps.

|

|

Monday:

|

Measure effluent and check dilution rate.

|

|

Tuesday:

|

Approaching steady state, full sampling.

|

|

Wednesday:

|

At or near steady state, full sampling, ready to harvest

and take down chemostats if stabilized.

|

|

Thursday and Friday:

|

At or near steady state, full sampling, ready to harvest

and take down chemostats.

|

|

Friday:

|

Finish cleanup of Carboys, etc.

|

The scheme outlined above is 10-20 generations. Attempts with fewer generations do not

reliably hit steady state.

However, at more than ~25 generations, you have evolution to worry

about. Some strains take longer

than others to reach steady state.

Do sufficient sampling to convince yourself that the chemostat really is

at steady state before you harvest.

We use filter-sterilization. You'll autoclave an empty carboy with the appropriate

fittings, make up the media in a 'mixing' carboy and then filter it into your

sterile carboy as described below.

The media vessel is made up of the 10L glass carboy with a

bottom spout, and a Cork Assembly. The bottom spout is fitted with 1/4"

tubing, with a clamp, and the male part of a 'quick connector,' which will

eventually connect to the female part of the quick connector on the media line

running to the chemostat. Use of

these connectors allows the carboy to be autoclaved separately from the

chemostat and its attached media line.

The Cork Assembly consists of a big silicone stopper with an air filter

and a media port outfitted with a connector to fit the filter. This media port

will connect to a modified 1 L filter through which the media will be

filtered.

To make the Cork

Assembly, carefully use a cork borer/awl to make a hole from the bottom to the

top of the cork. Make 2 of these

holes. Then fit a length of rigid

tubing (we use a 1200ml pipet tip with the small end clipped off after insertion, for

unrestricted flow, but you could use metal, or some other autoclavable but not

brittle material), into each hole, being careful not to injure yourself or the

rigid tubing. Whatever you use, it

should be monitored for cracks and may occasionally need to be replaced. Then attach a short piece of 1/4"

tubing (about 4 inches) to one of the ports, and attach a carboy vent filter to

it. To the other port, attach a

longer piece of tubing (about 7 inches), and attach a filter adapter to

it. We use Corning filters, and

the adapters come with them. They

can be autoclaved several times, but should be monitored for cracking, as this

is not their intended purpose.

Figure 3. Setting up the carboy.

Now let's talk about Origami. One nice way to wrap the tubing ends, taught to me by Frank

Rosenzweig, is diagrammed below.

It is secure, yet can be undone with one hand.

1. Fold a 4 in

x 4 in piece of foil in half top-to-bottom and insert the tubing.

2. Fold it in

half again left-to-right.

3. Fold the

flap back in on itself so the edges meet the tubing.

4. Fold the top

corner on the diagonal to lock the end in the packet.

5. If desired,

apply autoclave tape to the foil.

When you go to access the connector, you can unfold back to

step 2 or 3 with the foil loosely covering the end. It will be protected while you arrange the other piece of

tubing.

Figure

4. Foil Origami

Make sure to calculate how much media you'll need, and

include additional carboy connectors as needed. Keep in mind that you can NEVER

put more than 8 carboys on the carboy shelf at one time.

To prepare the empty carboy for autoclaving, start by

attaching a male quick connector to the bottom tube. Then pipet 20ml of water into your clean carboy. This allows for steam sterilization of

the interior of the carboy. Then

insert the cork assembly into the top of the carboy, and give it a firm push

in. Use the green electrical tape

(Scotch #35), to tape down the cork.

Run one strip from the glass carboy neck on one side, tightly over the

cork and in between the two ports, and onto the other side of the carboy neck. Then run another piece of tape in a

ring around the neck, overlapping with the first strip of tape. This should prevent the cork from

popping out in the autoclave.

Next, use your favorite foil origami method to cover the media-in port

on top, and the media–out port on the bottom. Finally, place a metal clamp on the tubing of the media

port.

Autoclave on fluid cycle, for 20 minutes, and NEVER clamp

off the air vent, as it may cause the carboy to explode in the autoclave. Since the volume of air in the carboy

is so large, autoclaving on the fluid cycle is required in order to prevent

breakage. It's best not to exceed

20 minutes of sterilization time, because of all the plastic components that we

expect to survive multiple sterilization cycles.

You'll need to fetch

enough water for your media, from the 2nd floor distiller. Take a cart, and all the water hauling

carboys you'll need. You should plan on making no more than 40L per day. We don't have the water hauling vessels

to transport much more than that at a time, and if you go back for more later

in the same day, you will probably find that the water is too warm to use,

since the distiller is replenishing the volume you took. Always use room temperature water to

make media. If you do have to get

more on the same day, the spigot on the right may have cooler water than the

one on the left. Quickly touch the

glass to check. Also, the spigot

on the right dispenses at twice the rate of the one on the left, so you can

fill 2 carboys from the right spigot in the same time it takes the left spigot

to fill one. Use the plastic

carboys first, and if you have to, use one of the glass ones.

Never use hot water to make your media. If you have to wait a day to allow the

water to cool, filter sterilize the 10X sugar. The salts can sit around for a week without being sterilized.

Completely dissolve your 10X salts (plus limiting nutrient),

and 10X carbon source in separate 2L beakers. Some salts need to dissolve overnight. When these components are dissolved,

and adjusted to the proper volume (according to how many carboys you're making

ex. 3L of 10X for 3 10L carboys), measure 1 L each of the 10X components in a 1

L glass graduated cylinder, and pour it into a glass 4L graduated

cylinder. Then pipet 10ml each, of

the 1000X Vitamins (thawed in advance) and the 1000X Metals into the 4 L

cylinder. At this point you

should have 2 Liters and 20 mls in the 4 L cylinder. Top to 4 L with room temperature glass distilled water, and

pour into the mixing carboy. The

4L cylinder can be unwieldy, so use one hand at the top to hold it steady, and

the other hand to lift the bottom.

You'll have to pour slowly, since the opening of the carboy is

relatively small. Refill the

cylinder 1.5 times, to reach a total of 10L in the mixing carboy. Turn on the

large stirplate to low, so that the large stirbar is not out of control. Stir until thoroughly mixed, at least 5

minutes, and proceed to filtering the media.

The media will be filtered into the cooled sterile carboy by

manipulating a 1L bottle top filter, attached to a wide mouth 100ml bottle (or

a larger one if no 100ml bottles are available). The filter plug will be removed from the usual vacuum

attachment with sterile tweezers so that it can instead serve to funnel sterile

filtered media into the carboy.

The vacuum will be attached to the air vent on the carboy. Filtering will take ~30 minutes. Although the filters are nominally for

only 1 L, this is the most consistent method we've found for sterilizing this

volume of media.

So gather the following:

- 1 10

L sterile glass carboy (ambient temperature), labeled and sterilized with

plastic piece for filter attachment foiled and clamped off on top, and a

male quick disconnect outlet foiled and clamped on the bottom

- 1 10

L non-sterile glass 'mixing' carboy, with a large stirbar, and a length of

tubing sufficient to reach the bottle top filter that will be below

it. The tubing should have a

large adjustable clamp, to keep the filter cup from overflowing.

- 100

ml wide mouth bottle (sterile), labeled with its corresponding carboy#,

date, and your initials.

- 1 L

bottle top filter to fit the bottle (Corning 431174)

- Metal

tweezers

- Ethanol

for flaming

- Bunsen

burner

- Ring

stand with 3-prong clamp to hold bottle during filtration.

- Large

polypropylene tub to catch spills.

- Claim

an area to work, Set the sterile carboy and ringstand in the large

tub. You want the tube with

the filter attachment piece closest to the ringstand. Adjust the 3-prong clamp to a

couple inches below the filter attachment piece. Set the whole tub aside.

Figure

5. Getting ready to filter: The Carboy.

- Light

the Bunsen burner, and closely position the tweezers, uncapped EtOH, and

100ml bottle. Loosen the origami foil on the top media port of the carboy.

Figure

6. Setting up the filter.

- Loosen

the cap on the bottle. Open

the top end of the filter bag, and remove the large sterile filter cover

from the package, keeping it sterile. Place it on the bench, sterile side up. Put the sterile bottle cap,

sterile side down on the sterile filter cover.

- Carefully

remove the filter from the package keeping it sterile where it will screw

onto the bottle, and where the vacuum usually attaches. Screw it securely onto the bottle.

- Dip

the tweezers in EtOH, shake off excess, and flame them. Use them to pull out the filter

plug from where the vacuum usually attaches.

- Attach

the filter to the filter adapter that was autoclaved on the carboy's media

port (on the cork assembly).

- Clamp

the bottle into the ring stand, exactly upright, being careful not to tug

on the tubes coming from the carboy.

Figure

7. Final assembly of filter set up.

8.

Move the tub containing the sterile carboy and ring stand

onto the floor below the vacuum.

9.

Attach the vacuum hose to the vent filter on the sterile

carboy.

10. Route the

clamped output tube from the mixing carboy into the top of the filter, and

secure it to the top edge with tape.

11. Double

check all filter connections (to bottle, and to carboy).

Vac OFF Vac ON

Figure

8. Turn Vacuum on LOW

12. Turn on the vacuum (Only half a turn!) and unclamp

the output hose from the mixing carboy. You can adjust the large clip to

constrict the flow if necessary (2-4 clicks seems to work well). The filter should always be covered

with media throughout this process.

13. Once the filter cup has started filling, remove the

metal clamp on the tube between the filter and the carboy (the media

port). The 100 ml bottle will fill

first, and then overflow into the carboy.

Make sure vacuum lines aren't clamped.

14. Do not

walk away! This system is fraught

with potential for spillage, so monitor it closely. Stay nearby, and make sure the filter is not going dry, or

overflowing. Adjust the number of

clicks on the large clip to get a good balance. You may notice that the vacuum pulls the cork downward into

the carboy. There have been

occasions when the vacuum is too high, and the cork gets completely sucked into

the carboy. If that happens, you

have to autoclave another carboy, refilter your media, and hack the

sucked-in-cork to pieces with a pair of scissors (see Disaster Index). Don't turn the vacuum on more than a

half turn of the knob!

15. When the

mixing carboy gets close to the bottom, turn off the stir plate, and tilt the

carboy toward the outlet tube until it is drained.

16. When the

media is all filtered, unclamp the 100ml bottle, and tilt it toward its outlet,

so that media runs into the carboy, and you have some headspace in the bottle.

17. Make sure

there is no media in the tube running from the filter to the carboy, and clamp

it tightly with a metal clamp.

Then turn off the vacuum, and slowly release the vacuum by removing the

cork from the trap.

18. Detach

the filter and bottle from the carboy's media port. Keeping sterility, cap the bottle. Then toss the filter, and re-cover the media tube with foil.

Move the carboy to the shelf above the chemostats (ask for

help if needed). Place the 100mL

bottle of media in the 30C incubator, and watch it for a couple of days, to see

if any of your carboys may be contaminated. Rinse the mixing carboy, along with any tubing that you

used, and the 4L graduated cylinder with DI water, six times each, no soap or bleach,

ever.

NEVER put more than 8 full carboys on the carboy shelf!

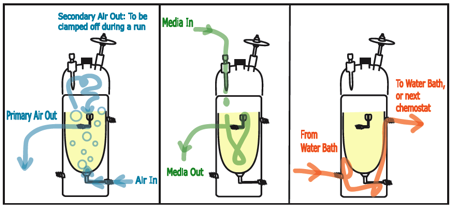

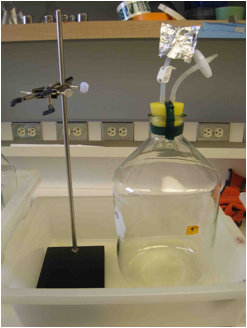

Figure

10. The three systems of a chemostat.

Our chemostats are custom made for us by a scientific glass

blower. They require 3 systems

functioning together to work properly.

They are diagrammed here as Air, Media, and Water jacket, respectively.

Air is pumped from an aquarium pump, through a gas washing

bottle, which has a coarse glass frit that disperses the air stream into

bubbles within the chemostat. These

bubbles not only aerate the media, but they also work to keep cells

suspended. Additionally, the

positive pressure created by the air keeps the effluent track moving quickly in

the correct direction, helping to prevent contamination. The gas washing bottles serve to

humidify the air, reducing evaporation.

The air filter on the top of the chemostat is clamped off after

autoclaving, to direct the air out through the effluent track.

Media drips into the chemostat from tubing that connects a

media carboy with the media port on the chemostat. The flow rate is controlled by a peristaltic pump, which

massages media through pump tubing that is part of the media line. When the media level reaches the top of

the outflow cylinder, it exits by gravity flow, plus the positive pressure

created by the air flow pushes the overflow media out through the effluent

track.

The temperature of the inner growth chamber is regulated by

a water jacket. Water is pumped

through the jacket by a circulating waterbath which is set to an appropriate

temperature.

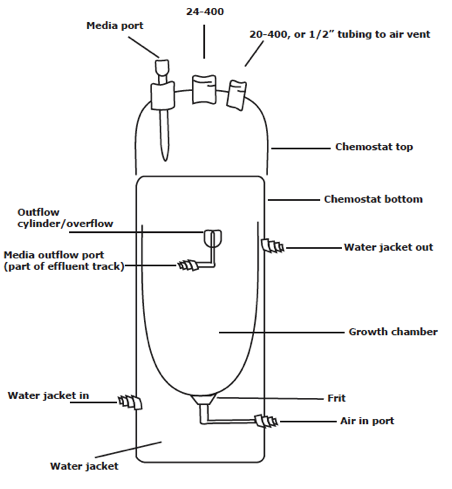

Figure 11. Anatomy of a Chemostat.

The chemostats should always be handled with great

care. They are glass, and have

many parts that could easily break off if impacted or handled roughly.

Replacing them is costly, in terms of both time and money. Be especially careful of the Pasteur

pipet-like media port on the lid of the chemostat. It wants to break off with very little pressure.

When chemostats are brand new, we want to check them out to

be sure they are functioning the way they should. Sometimes, there may be a glass seam that isn't completely

sealed, and the chemostat might have to be sent back. Here are the tests we usually run for each chemostat, before

it can be trusted for an experiment.

- First,

fit the chemostat's air-in and effluent-out ports with tubing (Wet the

glass with water first to minimize the pressure you put on the

joints). Route the effluent

into a beaker, and clamp off the air line. Fill the chemostat with water, until it overflows into

the beaker. Watch to be sure

the water level is at the top of the outflow cylinder. Check it after 20 minutes or so,

to be sure there is no change. Continuing to drain to below the top of the

cylinder may indicate a leak where the outflow tube attaches to the side

of the chemostat.

- Take

the top of the chemostat, and put caps on the 2 capable ports. Turn it upside down in the sink,

and fill it with water. Some

water might come through the media port, but you should be able to check

for leaks this way.

- Outfit

the chemostat with a media line, and a proper air line (see Setting up a

Chemostat for a Run, below).

Foil the ends and autoclave it. Fill the chemostat with sterile media, and start the

water jacket. Nothing should

grow. I usually leave it up

for a week before deciding it's really still sterile. If something grows, there is a

leak between the water jacket and the inner chamber, or possibly in the

chemostat top.

If the chemostat passes these tests, it's ready to be

measured and outfitted. With the

air bubbling, fill the chemostat with water and put the top on, air vent

clamped off, until it finishes overflowing. Then pour the water into a graduated cylinder to measure the

working volume. Chemostat volumes

vary because they are hand blown.

This is ok as long as the volumes (and D's) are similar enough that they

can run on the same pump. The

following table shows the unaltered working volumes of the chemostats we

have. We are working to find a way

to alter volumes, so that 4 can run per peristaltic pump.

|

Chemostat

|

Volume

|

Pump#

|

|

F1

|

165

|

3

|

|

F2

|

170

|

3

|

|

F4

|

175

|

3

|

|

F5

|

230

|

2

|

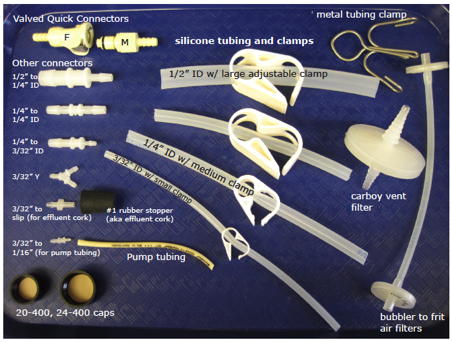

|

F6

|

230

|

2

|

|

F10

|

230

|

2

|

|

F11

|

230

|

2

|

|

F7

|

235

|

1

|

|

F8

|

240

|

1

|

|

F9

|

240

|

1

|

|

F3

|

195

|

Too different

|

|

F12

|

265

|

Too different

|

Table

2. Working volumes of unaltered chemostats.

When setting up a new chemostat, there are a few things to

consider. Gravity can work for us,

to keep our chemostats from getting contaminated. We employ glass jars to elevate the chemostats, so that

media or cells cannot backtrack to the chemostat through the effluent track,

resulting in the introduction of bacterial contaminants, or weird

subpopulations of yeast into the chemostat. Elevating the chemostats increases the downward angle of the

effluent track, reducing this risk.

This downward angle should continue from the effluent jar to the 2L

flask down below the chemostat table.

You should secure this line to the table with tape, eliminating any

upward slopes. See photo

below for a view of the effluent track.

When fitting the chemostat with tubing, set the chemostat in

place on the glass jar and ring stand, and fit the effluent track to an

effluent jar to be sure it reaches the jar, but doesn't have a bunch of extra

length to introduce weird slopes.

Figure

12. Downward angle of effluent track prevents contamination from reverse flow.

Aeration is a critical component for the properly

functioning chemostat, and a problem with the aeration in a chemostat can end

an experiment before it's started.

Low aeration effectively increases the volume of the culture in the

chemostat, causing an incorrect dilution rate. Vigorous bubbling also ensures that the culture is properly

mixed. Once your chemostat is

autoclaved, there are only a few things you can do without compromising

sterility (See Chemostat Troubleshooting).

At the beginning and end of a run, consider the air line

leading up to the chemostat's frit.

It should be unobstructed, and the same length and diameter tubing as

for the other chemostats. You

would be wise to test it before you autoclave it.

The aquarium air pumps

emit some kind of oily residue over time, discoloring the tubing, and coating

the inside of the gas washing bottle. We replace the water in the bubbler

before every run to prevent a buildup of the residue. When you see that the tubing is beginning to be discolored,

it's time to replace it. If there's

oily residue in the bubbler itself, you'll need to wash out the bubblers.

- Empty

bubblers and over-fill with isopropanol. Allow to sit without bubbling one or two hours, turning

air on for a few seconds, 2-4 times during that period.

- Use

a funnel to pour the isopropanol into a jug for reuse or disposal.

- Check

for oily residue, and repeat if necessary.

- Empty,

rinse several times, being sure to flush the entire track. One way to do this is with the

water on LOW, connect the bubbler to the faucet, so that it fills up to

the top, and spills out the other tube. Leave it flushing for a couple of minutes. Then connect the next one in the

same way.

- After

flushing, dump out the water, and blow air through the same track to get

the last bit of water out from behind the frit.

- Over-fill

with fresh di water. Allow to

bubble overnight

- Rinse again with di water, then empty and leave air on

overnight to dry.

- Refill with sterile distilled water.

The aeration in the

chemostat should be vigorous, and after your run or after a frit invading

strain, you may notice that the bubbles are smaller than they should be. Eventually they get to be tiny like

champagne bubbles, and this will undoubtedly affect your experiment. Not only is there low dissolved gas,

there is also a change in working volume, making your dilution rate wrong.

To deal with this issue,

we excessively clean the frit after each run, and periodically bake the bottom

half of the chemostats to incinerate the trapped cells. Remove all tape, then cut the tubing

(along the length of the tubing where it is on the glass) to remove it without

stressing the glass joints. Arrange to

use the drying oven in the autoclave room, and bake them in metal pans without

cloth or tape, for 4 hours at 300C.

Use the metal pans with fabric lining to store, transport,

and autoclave the chemostats. Two

chemostats fit nicely in each pan.

You will quickly notice that there is no good way to lay them down, but

you certainly don't want them teetering in an upright stance. The best option is to lay them down

with the capped port and the air port down, and with the fragile media port

up. However, when autoclaving, you

must be sure that the air vent tubing is not kinked.

If you're running multiple

chemostats, you should consider which ones to use according to which group they

fall into based on their volume (see Table 2).

Before assembling the chemostat, check to be sure there is

not water under the frit. If there

is, hook up an aquarium pump, and turn the chemostat upside down to gently push

water from under the frit. Also

blow air through the chemostat's media line attached to the chemostat top. Failing to remove this water will

result in wet air filters, and reduced air flow.

Put the top onto the chemostat, positioning the air vent

over the outflow cylinder. This

will be helpful when inoculating, and when adding media, to insure that neither

go straight into the effluent.

Decide how you will arrange the media flow tubing network

that will connect the carboy(s) to chemostat(s). If you want to run multiple chemostats off one media carboy,

you need to make a Y connection out of scrap tubing. Make sure you put the right connectors on all the ends. If you want to run chemostats off

multiple media carboys, you will need a more complicated branching

connector. Make the connector

piece and wrap foil over all the ends. Make a sketch of the media track to be

sure you have all the components you'll need (Proper half of quick connector,

pump tubing, clamps, etc.). Then,

assemble the tubing network according to your set up, and blow air through it

to remove any water.

Since pump tubing is reusable for several runs, we color

code the tubing in groups according to which pump they were run on, and keep

them twist tied together when not in use.

If you're not sure about the tubing, ask the person who ran the last

chemostats with that tubing, to be sure it is still good. Markers for marking tubing are in

the pump tubing box. Use pliers to

remove marker caps, and to fit tubing with connectors (they're kind of sharp).

Figure

13. Set up new pump tubing using pliers and paint pens, or re-use a set of

tubing.

Once the media line is complete and attached to the media

port of the chemostat, foil the ends of the media and air tracks, double

checking that the air vents and effluent corks are attached to the right ports

before autoclaving. See Figure 14 as an example set up for 2 chemostats

running off of one carboy.

Autoclave the chemostats

and effluent jars on fluid cycle with a 20 minute sterilization time, making

sure the air vents are not clamped or kinked, AND that the caps are loose. The cycle will take about an hour

total, so plan to go down and get them before someone else does. If a cap has fallen off, or a cork

popped out of a carboy, carefully put it back in place immediately to keep it

sterile.

While the autoclave is running, check that the bubblers are

filled and ready to go. If they

aren't full to where the springs attach, dump them out in the sink or in a

beaker, and refill with sterile distilled water. While it is difficult to keep them perfectly sterile, we

should keep them as sterile as possible.

Bubblers can get contaminated.

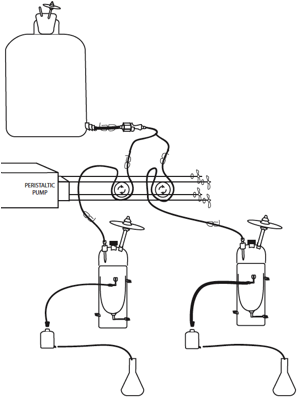

Figure

14. Two chemostats running off of one carboy:

Media flows from a 10 liter carboy, through tubing to the chemostats. Flow rate

is controlled by a peristaltic pump that massages media through pump

tubing. Media flows out of the

chemostat into an effluent jar. The

cork of the effluent jar can easily be transferred to a 50ml conical tube for

sampling. The bottom spout of the effluent jar drains into a 2 L flask below,

where it collects until sampling time when it is measured (to calculate the

dilution rate), and discarded.

After they've cooled, set the chemostats up on their

pedestals, and secure them with a 3-prong clamp. Don't over-tighten, as the glass is fragile. Ask someone to help you lift the

carboys onto the shelf above the chemostats. You want to set the carboy onto the shelf gently, which is a challenge because it

is quite heavy. If you feel at all

unsafe lifting the media yourself, ask someone to help.

Now you're ready to start making sterile connections.

- Set

up the effluent bottles, down in front of the chemostats, and insert the

effluent cork in the top. Run the effluent jar tubing down to a sterile 2L

flask below. Be sure to

keep the foil in place on the flask, to minimize evaporation and

contamination. This track

serves as the path of least resistance for the media and air flow.

- Now

you can turn the air on. Make

sure the 'bubbler' (aka gas washing bottle) is full of water up to where

the springs connect, and plug in the air pump. The bubbler should bubble. Connect the output of the bubbler to the sterile inline

filter attached to the chemostat.

- Now

for the most critical connection:

the media. Loosen the

foil on the carboy's bottom port, and on the media line's quick connect

end, and then quickly but calmly connect them, being careful to not touch

the very ends of the connectors.

You might have to use some force to make the connection, and you'll

hear a click when they're connected.

It's a good idea to practice connecting these ahead of time to get

a feel for it. If you should fumble and touch something that should be

sterile, use ethanol to sterilize the connector, and keep an eye out for

contamination during the run.

- Now

you can fill the chemostat with media. Using gravity instead of the pumps is fastest, and

keeps you from having to reset the pumps. Unclamp the tubing, and in a minute, the media will

begin dripping into the chemostat.

Make sure it is bubbling.

Once they have started filling, and you've verified that they are

bubbling, you can leave it unmonitored for up to 30 minutes, but don't

forget to clamp them off when they start to overflow. The whole carboy will empty onto

the floor if you forget about it.

- While

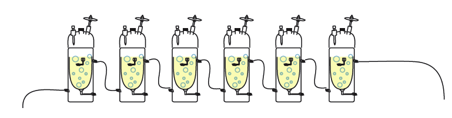

the chemostat is filling, make the water jacket connections to the

circulating waterbath. You

can daisy-chain up to 6 chemostats together, on one waterbath, with only

one degree difference between the first and the last. The image at the top of page 1

shows the daisy chain set up.

If the waterbath is set at 30.5C, the coolest chemostat will be

29.5C. Double check all your

connections, and make sure the tubing is all unclamped and unkinked before

you turn on the waterbath pump (the button on the front). Stand by with a 2L beaker, so you

can add DI water to the reservoir as the chemostat jackets fill. The water level in the reservoir

should come up to the divet, about an inch below the top of the

reservoir. It takes about 2L

to fill the jackets of 4 chemostats.

- After

the chemostat is filled with media and begins to overflow, you need to

close the clamps above each chemostat. Then you have 2 options for the timing of the

inoculation: you can wait a

day to be sure there is no contamination, or if you're in a hurry, you can

go ahead and inoculate.

Once the chemostat is filled, you can inoculate. It's best to inoculate the chemostat

with fresh overnight culture made from a fresh colony. Plan on 2-3 days to grow colonies

streaked from a frozen glycerol stock, plus another day for the overnight

culture. You can grow the overnight

in YPD or in chemostat media. If

you use YPD, you might want to spin down 1 ml of culture and resuspend it in

water. Inoculate through the black

cap on top of the chemostat. Be

quick but careful to minimize risk of contamination. Be careful not to squirt the inoculum into the outflow

cylinder, or onto the sides of the growth chamber. After the inoculation, there is a 24 hr waiting period

before you turn the pumps on, so that the culture can grow to saturation. Wait to load the pump heads.

Your chemostats should be nice and dense before you start

the pumps. Usually this takes

about 24 hours after inoculation, but might vary in some cases. You might want to top off the chemostat

volume via gravity, before loading the pump heads, but be careful not to let

the chemostats overflow more than a few drops before clamping the line and

loading the pump heads.

The best way to be sure that the pump rate is right, is to

use the same pump and pump tubing that was used in a previous run, that has

shown a correct dilution rate. To

help with this, pump tubing is grouped and color-coded according to which pump

it has been run on. The pumps can

be difficult to adjust, and you don't want to change the rate during a run, if

it is avoidable.

If you have to adjust the pump, you have a couple of

options. You can use a 'flow rate

tester' before the experiment starts assuming you have a similar piece of pump

tubing to what you'll be using in the experiment. Our flow rate tester consists of a water supply with tubing

leading through pump tubing, to a 10ml glass pipet. We use a buret clamp on a

ring stand, to clamp the pipet in an upright position, and load the pump tubing

into a pump head. Measure the

amount of time it takes the water to fill 1ml in the glass pipet, and calculate

D for the highest and lowest volume chemostat that will be on the pump. Adjust pump if necessary, and repeat

until D is between .16 and .18, then time 5 mls to confirm.

The other option is to wait until you've loaded all your

pump heads and turned the pump on (instructions below), then see how long 5

revolutions of the pump head takes, and adjust as needed to achieve the same

rate as in previous runs. Neither

method is perfect, and you may still have to adjust the pump rate during the run. If it is corrected early in the

experiment, it should be fine.

Beware of Pump #1, as tiny adjustments have big effects.

|

pump

|

chemostat

|

Seconds per 5 revolutions

|

chemostat volume range (ml)

|

|

1

|

F7, F8, F9

|

27

|

235 to 240

|

|

2

|

F5, F6, F10, F11

|

28

|

230

|

|

3

|

F1, F2, F4

|

36

|

165 to 175

|

Table

3. Example pump rates for chemostats

Check the pump head to be sure it has 2 white washers, one

on each post, front and back.

Replace if necessary. Load

the pump tubing into a pump head, and load it onto the pump. If you'll be running multiple pump

heads on one pump, BE SURE to include dummy lines in the other pump heads,

running water to and from a water reservoir next to the pump. Each head should be moving liquid to

simulate the load the pump will be working with during the experiment. Not including these 'dummy lines' will

result in an inaccurate flow rate estimate.

While loading more than one pump head per pump, be sure to

orient the tubing the same way, since the pump will only be turning in one

direction. It can turn in either

direction, so either way is fine, but be consistent from one head to the next.

To load the pump tubing into the pump head, hold the pump

head in your left hand, with the male post facing up, and the in/out tubing

track toward you. Remove the top

half of the pump head, and loosely wrap the pump tubing around the center of

the pumphead, entering and exiting at the tubing track. Hold the tubing loosely in place where

the tubing track is, with your left thumb. Put your right thumb, (or the special tubing-loading tool)

into the gap between the rollers in the pump head, and push the rollers

counter-clockwise, one full turn, until the tubing is seated within the pump

head. It will stretch out a little,

so adjust your left 'holding' thumb so that the tubing is in the tubing

track. Then, still keeping the

tubing in its track, put the top half of the pump head back on. It should go on clean, with a big click,

and no interference from out of place tubing. If you think the tubing might be pinched, turn the center

post back and forth a couple of times, to be sure it is moving freely. If it's pinched, start over. It will sever your tubing if not loaded

properly.

After all the heads are loaded with tubing, check to be sure

all the pump's posts are screwed in all the way. Sometimes they are loose from the last run. Then, load the pump head onto the posts

coming off the front of the pump, along with any dummies, with the tubing

coming off the top of the pump heads.

For each additional pump head, be careful not to disturb the previously

loaded heads, as the tubing could come loose and have to be reloaded. Using a tool to turn the center post

(the tubing-loading tool, a screwdriver, or scissors work), make sure each head

fits together tightly, with no gaps.

Secure with a washer and wingnut, not too tight. If you are loading 4 heads onto one

pump, you'll also need to include a support foot, after the pump heads, but

before the washer.

Check the orientation of the tubing (be sure that the 'from

carboy' side of the tubing is the same for all heads on the pump. Determine the direction you want the

pump to go, and place a tape arrow indicating which way to flip the switch.

Once all the heads are properly loaded, they are acting as the

ultimate flow control for the media, so you should open all clamps in the media

line.

Now, you can flip the switch in the appropriate direction,

and media will start to flow. If

you didn't top off by gravity, it will take some time to fill any air gaps that

are in the line. Avoid disaster by monitoring the pumps for the first half hour

after you turn them on (see Disaster Index in the Appendix if something does

happen).

If you are just checking the flow rate, come back in 30

minutes to see if the pipet is filling with water yet. If it is, grab a timer, a calculator,

and a notebook. Start the timer

when the meniscus of the water is at one of the mL graduations on the

pipet. Make sure you are eye

level. When the level has raised

by 1mL, calculate the D for the lowest and highest volume chemostats that will

be on that pump. If the range of D's

isn't between 0.16 and 0.18, adjust the pump and try again. Only very small adjustments are needed,

and Pump#1 is especially touchy.

Bring your patience for this one.

Once you get a good 1mL measurement, confirm it by timing a 3-5ml

measurement. After adjusting the

pump, cover the knob with a white cap, to insure that it doesn't get bumped.

If this is the actual experiment, you need to stick around

to see that effluent is actively draining to the 2L flask below. When you are sure that it is, empty the

flask, and note the time. You will

use this timepoint to calculate the flow rate.

Below is an example of 'dummy lines'. They run water in and out of a flask to

simulate the load of another chemostat line.

Figure 15. Dummy lines simulate active chemostat

lines, so you don't have to adjust the pump.

The chemostats ideally should be sampled every day, particularly

when collecting sweep data. Twice

a day is not overdoing it for competition experiments. Try to be as consistent as possible

about your technique, and write down anything that you change.

A daily sampling regimen includes measuring effluent volume,

OD, Klett reading, Coulter count, Coulter mean cell volume, looking at the

culture under the microscope, making a glycerol stock, viable cell counts on

YPD and minimal plates (and possibly on selective plates), and possibly

sampling for RNA and DNA. Depending

on the number of chemostats and plates, the whole process, including setup and

counting the plates from earlier in the run, takes anywhere from an 1-4 hours.

When you need to change the media, try to do it after

sampling to avoid any chance of a perturbation. Note media changes in your records.

To take a sample, place the styrofoam backed conical tube

rack next to the outflow jar.

Remove the cap from the tube, and place the sampling cork into the

tube. Cover this with a loose

piece of foil, and place the conical tube cap over the top of the effluent jar.

Take care to NEVER elevate the sampling cork! Contaminants could easily be washed into the chemostat.

While the tube is filling, pour the effluent into a glass graduated cylinder

and write down the volume. You'll

use this measurement to calculate the dilution rate later. After 20 minutes, you should have

enough culture for typical measurements and stocks.

Figure

16. Taking a sample during a run.

Before you begin sampling, organize all the required plates

and diluents for sampling and prepare to record your data (see below). Label all the required tubes for the

density measurements and serial dilutions and fill them with the right amount

of diluent. Label all the plates. Turn on all the equipment and check

that they're properly calibrated.

Run a clean sample of filtered Isoton II through the Coulter Counter to

make sure it's clear of excess particles, and refilter it if necessary.

Turn on the Klett at least 30 minutes before using it, and

put a water or media blank into place.

Check that the pointer is not bouncing off either side, but rather

somewhere in the middle.

Figure

17. Example of typical sampling:

Preparing tubes and plates ahead of time.

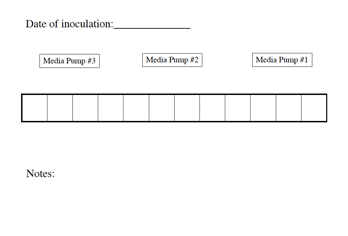

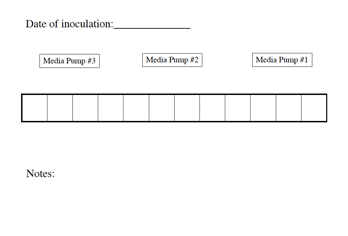

It is extremely important that your data be collected in an

organized and meaningful way. This will involve a layout sheet, notecards, and

an Excel spreadsheet. This system

serves to keep both a hard copy and electronic copy in case disaster strikes.

The notecards will be added to the lab's card catalog in Maitreya's office, and

spreadsheet will be added to the chemostat database on the server.

At the beginning of your experiment, start with a sheet that

summarizes your set up. Include

Fermenter number, which pump and pump head numbers you used, which carboy went

with which fermenter, and so on.

The blank forms are kept with the blank notecards.

Figure

18. Experiment Layout Sheet

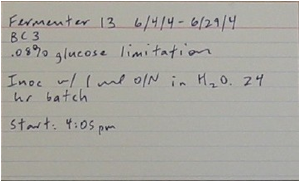

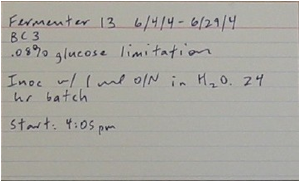

For the index cards, start with a header card (Figure 19)

with all the relevant information about the chemostat, including fermenter

number, strain, media composition, limitation, date and time started, method of

inoculation, and your initials. Upon completion of the run, you will add the

ending date as well.

Figure

19. Header index card.

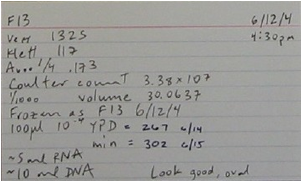

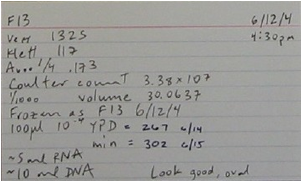

Each day, label all the fields on a new card (Figure 20)

before you start sampling. This

includes what dilutions should be done for all the measurements, what plates

need to be used, and what was written on the frozen sample. Each chemostat gets a new daily

card. Fill in the fields as you

take the measurements. Be sure to

write down any observations and illustrations of the look and smell of the

culture on the back of the card.

The card then goes into a small 'active chemostats' box. Pull the cards whenever you can fill in

another field, such as colony count or dry weight.

Figure

20. Sampling index card.

Once the chemostat run is completely finished, fill in the

end date on the header card, amend the entry in the chemostat spreadsheet with

the end date and any pertinent results (i.e., whether or not you harvested and

where you put the tubes) and type all the data into the computer. You could also input the data

periodically while the chemostats are running. Finally, clip all the cards together with a secure paper

clip and put them in the "Ready to be Filed" box, so they can be

filed in the card catalog. No

cards make it into the archives without first getting entered into the

computer. The server is

automatically backed up, and make sure your computer gets backed up regularly

as well. You may also want to burn

your data to CD once in a while and store it off-site, or upload it to the